Meet DatapointLabs+Matereality staff at the following events:

- Altair Technology Conference 2015: May 5-7, 2015 – Dearborn, MI, USA.

Silver Sponsor and APA Partner. Find us in Booth #10. - Simulia Community Conference: May 19-21, 2015 - Berlin, Germany.

Conference attendees. See "Developing a Constitutive Model for a Highly Deformable Latex Rubber with Implementations in Lagrangian Frameworks," presented by Christopher Basciano, BD Corporate CAE; Brian Croop, DatapointLabs, is a contributor. - 10th European LS-DYNA Conference: June 15-17, 2015 - Wuerzburg, Germany.

Exhibitor. See "Comparison of Crash Models for Ductile Plastics" in the technical sessions. - ANSYS Conference & 33rd CADFEM Users' Meeting: June 24-26, 2015 - Messe Bremen, Germany.

Exhibitor. See "Finite Element Analysis of Additively Manufactured Products" in the technical sessions.

DatapointLabs founder, Hubert Lobo, will deliver technical presentations focusing on aspects of validating material data for CAE at two conferences in June.

DatapointLabs founder, Hubert Lobo, will deliver technical presentations focusing on aspects of validating material data for CAE at two conferences in June.

- "Comparison of Crash Models for Ductile Plastics," by Megan Lobdell, Brian Croop, and Hubert Lobo, will be presented at the 10th European LS-DYNA Conference in Wuerzburg, Germany.

- Abstract: There is interest in quantifying the value of different material models being used in LS-DYNA today for the modeling of plastics. In our study, we characterize two ductile, yet different materials, ABS and polypropylene, for rate-dependent tensile properties, and we use the data to develop material parameters for the material models commonly used for plastics: MAT_024 and its variants, MAT_089 and MAT_187. We then perform a falling dart impact test, which produces a complex multi-axial stress state, and we simulate this experiment using LS-DYNA. For each material model, we are able to compare simulation to actual experiment, thereby obtaining a measure of fidelity of the simulation to reality. In this way, we can assess the benefits of using a particular material model for plastics simulation.

- "Finite Element Analysis of Additively Manufactured Products," by Megan Lobdell, Brian Croop, and Hubert Lobo, will be presented at the ANSYS Conference & 33rd CADFEM Users’ Meeting in Messe Bremen, Germany.

- Abstract: With the growing interest in 3D printing, there is a desire to accurately simulate the behavior of components made by this process. The layer by layer print process appears to create a morphology that is different from that from conventional manufacturing processes. This can have dramatic impact on the material properties, which in turn, can affect how the material is modeled in simulation. In the first stage of our work, we seek to test an additively manufactured material for mechanical properties and validate its use in ANSYS simulation using the Cornell Bike Crank model.

DatapointLabs' range of available Mechanical Tests has been augmented with M-209, Combined Loading Compression (CLC) test, which is used to acquire compressive strength of polymer matrix composites. The new test provides data on compressive strength and strain to yield and break, as well as a reference value of compressive modulus.

See the entire Test Catalog.

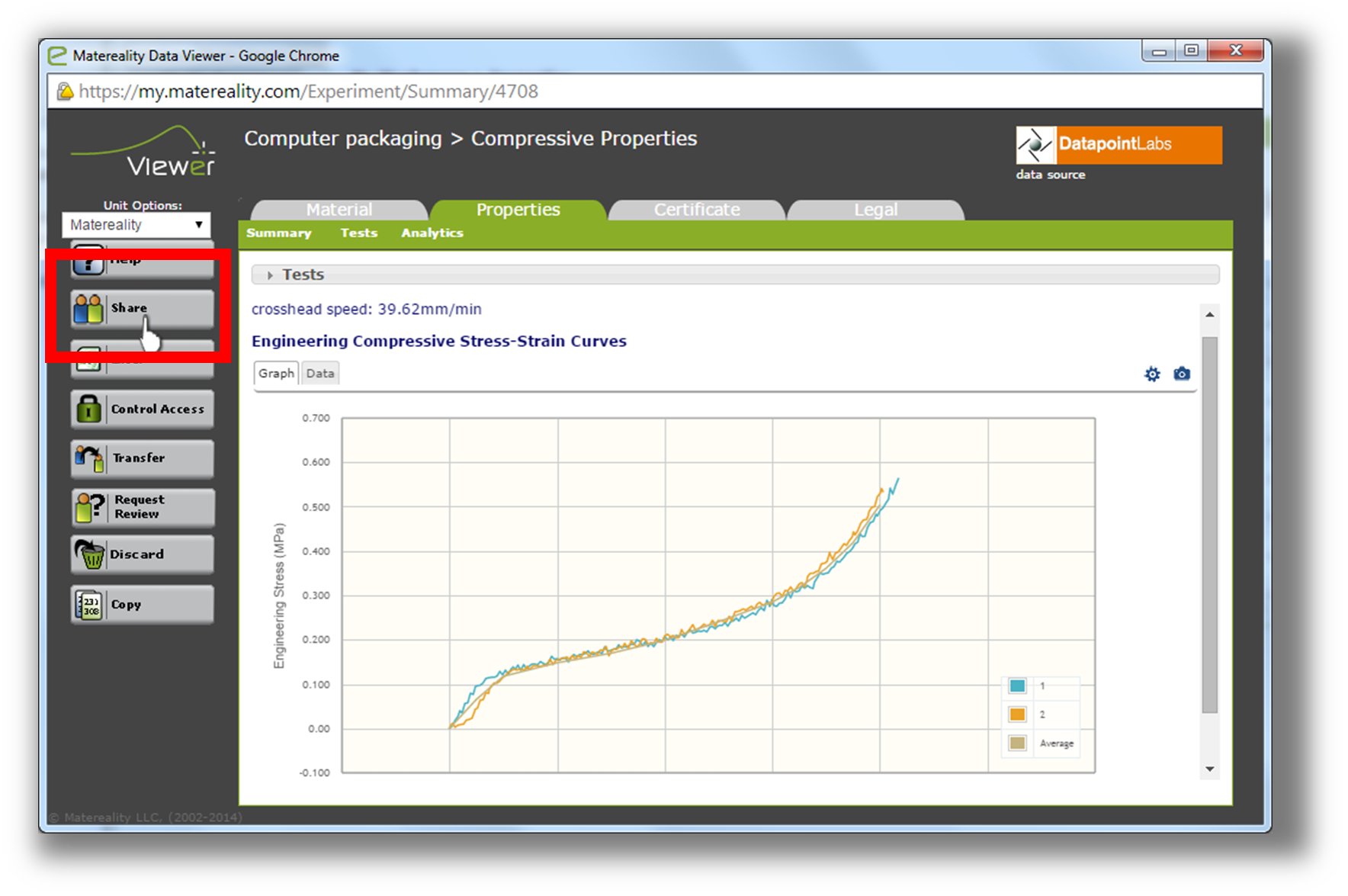

| A new video showcases Matereality's Workgroup Material DatabasePro solution, with tips on how product development teams can enhance collaboration within their group with Matereality.

Workgroup databases are useful when more than one person needs to have access to your material data. Matereality's browser-based software and CAE integration allow product development teams to build and maintain a productivity-enhancing material database containing materials information, properties, and CAE input cards, which is accessible by every member of your Workgroup. An upgrade to a Workgroup solution allows sharing to be in your control. Users can Share test results, reports, and even CAE-ready material cards. User logs allow product design teams to know exactly what data was used in each design. DatapointLabs direct-deposits your material data, test reports, and CAE input cards into your database. |

Click to view video |

about DatapointLabs

about DatapointLabs![]() strengthening the materials core of manufacturing enterprises

strengthening the materials core of manufacturing enterprises ![]()

95 Brown Road #102, Ithaca, NY 14850 USA | Toll-free: +1-888-DATA-4-CAE | Tel: +1-607-266-0405 | EU, tel: +353 1 442 9204 | info@datapointlabs.com