PVT data first gained prominence when it was used to model compressibility

in computer simulations of the packing phase of the injection molding

process[1]. Plastics are compressible at the high pressures used

in the injection molding process. During the packing phase, most

of the flow results from compressibility. This effect is modeled

using the PVT data. Further, after freeze off, the part begins to

shrink. If the plastic is semi-crystalline, the shrinkage is primarily

due to crystallization. PVT data has been used to model the volumetric

shrinkage of the plastic which is then translated into linear dimensional

changes. However, there have been several limitations in this step.

For reasons described below, the traditional PVT data does not describe

the true characteristics of the injection molded part and limits

the ability of these simulations to correctly predict the shrinkage

of semi-crystalline injection molded products.

Traditional measurements of PVT have used essentially equilibrium

methods; the specimen is equilibrated or is in a state of quasi-equilibrium

at each test temperature prior to taking measurements. Several modes

of measurement have been used [2]. These are outlined below:

1) Isothermal cooling measurements:

Starting from the melt, the polymer is equilibrated at the test

temperature before subjecting it to a compression cycle [3]. It

is then cooled to successively lower temperatures and the compression

process repeated to develop an equilibrium equation of state for

the material. This technique has been in widespread use but suffers

from severe drawbacks. By taking measurements while cooling the

polymer, the technique is intended to capture the correct crystallization

behavior of the plastic. We find from our experiments that this

is not the case. The process of performing compression cycles provides

the driving force needed for nucleation. Consequently, the plastic

crystallizes close to its melting temperature, missing completely

the supercooling effect which is so characteristic of the crystallization

behavior of semi-crystalline polymers. Compare the melting transition

in Figure 2 to the isothermal cooling transition in Figure 4. Most

importantly, it is not possible to replicate the unique “skin-core-skin”

crystalline morphology seen in injection molded products within

a PVT apparatus. The PVT data of the solid state is then an artifact

of the measurement and bears no resemblance to that of the injection

molded part.

2) Isobaric cooling measurements:

The plastic is heated to its melt state and then solidified under

a constant pressure [2]. The process is repeated at other pressures

to develop a complete equation of state. This is also a quasi-steady

state measurement conducted at very low cooling rates. Since the

specimen is not being subject to the compression cycles, it does

need the thermal driving force to crystallize. The supercooling

behavior is correctly observed resulting in transition temperature

shifts that correspond well with those seen by DSC. The pressure

dependency of the transition is also captured correctly. However,

it still suffers from the same drawback as the isothermal cooling

mode: the solid state morphology does not represent that of the

injection molded part. Moreover, several morphologies can be obtained

depending on the pressure at which the polymer is solidified [6].

3) Isothermal heating measurements:

Here, the polymer is taken through a step-wise heating process with

a compression cycle being performed at each equilibrated test temperature

[2]. While well suited to general polymer characterization, the

technique has a drawback in our situation in that it captures the

behavior of the polymer as it melts, rather than as it cools. However,

provided that the test utilizes an injection molded test specimen,

the technique does capture the true solid state PVT behavior of

the injection molded part. It should be pointed out that all three

techniques have equivalent in their ability to characterize the

melt state PVT behavior.

In this paper we present a hybrid scheme whereby we are able to

circumvent the problems faced by the above techniques using a combination

of PVT and DSC measurements. The solution is specific to the characterization

of the PVT behavior of semi-crystalline injection-molded plastics.

Principle

DSC measurements are made on an injection-molded specimen at the

same heating rates as those seen in the PVT measurement. These are

used in the analysis to calibrate the results from one apparatus

against the other. This calibration is necessary to ensure that

there is correspondence between the volume change upon crystallization

observed by the PVT apparatus and the heat evolution occurring during

this process as observed by the DSC. PVT measurements are then performed

on the injection-molded specimen as follows: isothermal heating

measurements are first performed in the solid state over a wide

temperature range. The specimen is then melted at a low pressure

and its melting behavior is recorded. A series of isobaric cooling

measurements are performed at several pressures well into the solid

state. The purpose of these steps is to uniquely measure the solid

state volumetric expansion coefficient and compressibility of the

injection molded specimen, to characterize the melt state PVT behavior

and to determine the slow cooling rate crystallization behavior

of the polymer at different pressures.

Next, high cooling rate DSC measurements are performed to characterize

the rate dependency of the crystallization transition. The purpose

of this experiment is to capture a characteristic high cooling rate

crystallization temperature and its corresponding crystallization

kinetics. The hybrid PVT model is then constructed from the data

gathered by piecing together the measured solid state PVT data of

the injection molded part with the measured melt state PVT properties.

The transition from melt to solid is constructed by transposing

high cooling rate DSC kinetics. The pressure dependence of the transition

temperature is obtained from the isobaric cooling experiments.

Apparatus

A Gnomix Research PVT apparatus [4,5] was used for the high pressure

dilatometry work. The apparatus is fully computerized and capable

of automated operation. It utilizes mercury as the confining fluid.

A Perkin Elmer DSC7 was used for the high and low cooling rate crystallization

studies. The apparatus was calibrated using indium and zinc standards.

Volatile sample pans made from aluminum were used to hold the specimens.

Materials and Methods

The test material was a commercial grade unfilled nylon 66 polymer.

The material was injection molded into test parts which were then

razor cut to the appropriate size.

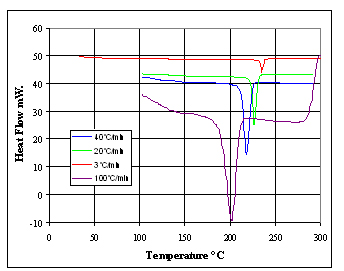

A 7 mg specimen was loaded into the DSC and melted at 3°C/min.

It was subsequently cooled at 3°C/min. 20°C/min, 40°C/min

and 100°C/min. The resulting heat flow curves are shown in Figure

1. Note that the curves are not normalized for rate. The peak analysis

is shown in Table 1. The dramatic shift in transition is noteworthy.

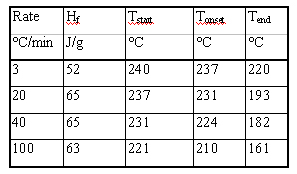

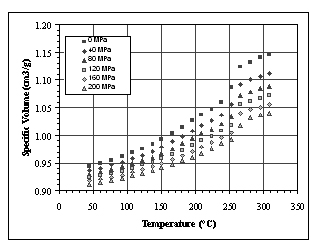

For the PVT measurements, 1.03 gm of the test specimen was loaded

into the dilatometer. The specimen was subject to isothermal heating

measurements at 10 °C intervals over a range of 30 to 150°C

and a pressure range of 10 to 200 MPa. The specimen was then melted

at 10 MPa (see Figure 2). Isothermal cooling measurements were then

performed at 10 MPa, 40 MPa, and 80 MPa. The resulting data are

shown in Figure 3.

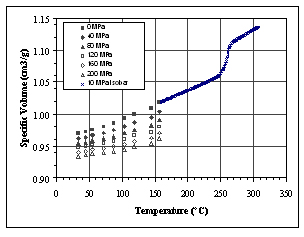

In a separate experiment, conventional isothermal cooling measurements

were conducted to provide a baseline for comparison. These results

are presented in Figure 4.

Data Analysis and Results

A Tait model was fit to the solid state of the PVT data derived

from the isothermal heating measurements. In a similar manner, a

Tait model was fit to the melt state region of the isobaric cooling

measurements. In both cases, data used for the fit excluded measurements

in the transition region, since the transition data was taken at

low cooling rates.

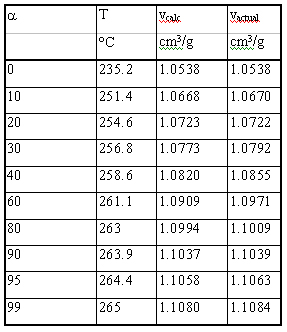

Before transposing data from the DSC to the PVT, an attempt was

made to correlate results from the two instruments. A partial areas

analysis was performed on the 3°C/min fusion peak observed on

the DSC. The corresponding conversion vs temperature data are shown

in Table 2. The total volume change upon fusion was taken from the

PVT data. This volume change was factored over the fusion conversion

data to obtain the calculated volume change at each temperature

as shown in Table. 2. The following equation was used:

v(T) = vs(Te) + {vm(Te) - vs(Te)}*a(T)

where

v(T) = specific volume at temperature T

vs(Te) = specific volume of the solid polymer at the end temperature

of crystallization, Te

vm(Te) = extrapolated specific volume of the polymer if it were

molten at the end temperature of crystallization, Te

a(T) = Degree of crystallization at temperature T

The value of vm(Te) was obtained by extrapolating the melt state

Tait model to the crystallization end temperature. This step serves

to eliminate from the equation, volume changes due to thermal contraction

that have occurred over the temperature range of the crystallization.

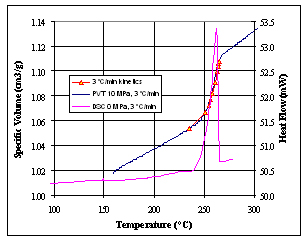

Figure 5 shows a plot of the calculated volume against that actually

measured by the PVT apparatus. The DSC peak is also shown. It can

be seen that the calculated points match the measured PVT data well.

A similar calculation (not shown) was performed to correlate DSC

crystallization peaks to PVT crystallization transitions with equally

good results.

With this correspondence, we conclude that the heat released due

to crystallization as measured by the DSC correlates well to the

volume change during crystallization as measured by the PVT apparatus.

It is reasonable to assume that this correlation should hold at

other heating and cooling rates. A partial areas analysis of the

high cooling rate DSC data was transposed to PVT data using the

total volume change occurring due to crystallization. The starting

point of the transition was taken to be at the crystallization onset

temperature observed from the DSC. Similarly, the crystallization

end temperature was also taken from the DSC.

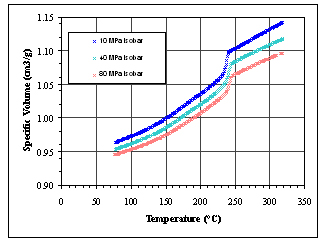

We observed from the isobaric cooling PVT data, that the crystallization

onset temperature varied linearly with pressure over the 10 to 80

MPa pressure range that we covered. This was in agreement with the

findings of He and Zoller [6]. Following their work, we did not

perform measurements at higher pressures due to the possibility

of alternate crystal morphologies being developed. In our analysis,

we assumed that the linear pressure dependency would apply at high

cooling rates as well. Accordingly, the crystallization transition

onset temperature at high pressures was shifted using this pressure

dependency function. For each pressure, transition volumes were

calculated between the crystallization onset temperature and the

crystallization end temperature. The resulting data are shown in

a composite plot (Figure 5) consisting of solid state isothermal

heating measurements on the injection molded part, calculated transition

volumes from DSC and melt state data from isobaric cooling measurements.

For purposes of comparison, the solid state PVT curves from conventional

isobaric cooling measurements are also shown. Note that these data

are significantly lower in the solid state compared to that of the

injection molded part, implying that the slow cooling rates of the

instrument impart a higher crystallinity and a different morphology

than that imparted by the injection molding process.

Discussion

The hybrid technique permits us to examine several aspects of the

PVT behavior of plastics. We observe the effect of super-cooling

on the crystallization temperature. Without considering the effect

of cooling rate, the super-cooling effect results in a crystallization

temperature of 238°C which is 30°C below the melting temperature,

Tm, of 265°C. This correlates well with independent measurements

by DSC. The introduction of high cooling rate effects further depresses

the crystallization temperature to 210°C. For the nylon that

we tested, the total shift in temperature amounted to about 55°C

at a cooling rate of 100°C/min. We also noted that the temperature

range over which the polymer crystallized was wider at high cooling

rates so that at 100°C/min, the crystallization effect was apparent

until 160°C. Consequently, the PVT curves in the transition

are not sharp as typically seen in conventional data, but instead

transition gradually into the solid state.

In modeling the crystallization at higher pressures, we have assumed

that the kinetics are not a function of pressure. This assumption

should be validated through high pressure DSC measurements but this

could not be carried out in our study. The assumption however, permits

us to provide a good first approximation of the volume change upon

crystallization at high pressures and high cooling rates. The ability

to make this calculation is based on our ability to accurately characterize

the change in the crystallization onset temperature with pressure.

The isobaric measurements provide us with a precise means to make

this measurement. In contrast to the isothermal compression methods,

the errors due to pressure induced crystallization are avoided because

the pressure is kept constant during the crystallization process.

In modeling the solid state behavior, we note the depression in

ambient specific volume of the isobaric cooled (or isothermal cooled)

specimen, 0.9402 cm3/g at 32°C and 0 MPa, as compared to the

isothermal heating (or hybrid) measurement of 0.9689 cm3/g. This

difference amounted to a 3% lowering in specific volume. Further,

since the specimen solidified in the apparatus does not possess

the skin-core-skin morphology, we observed that the thermal expansion

coefficients were also higher. The compressibility remained relatively

unchanged. This difference could account, in part, for the overprediction

of shrinkage by the CAE programs [7].

Plastics in injection molded parts cool very quickly. While the

skin layer will freeze at a very high cooling rate, the bulk of

the polymer will cool at a lower rate (in the 100 to 500°C/min

range). We based our choice of cooling rate of 100°C/min on

the point that we seek to develop a representative PVT model for

the bulk of the polymer. Further, this rate represents a realistic

upper limit to the measurement capability of the DSC. Thermal lag

effects, which are already quite noticeable at 50°C/min, could

become significant at very high cooling rates making it difficult

to assess how much of the shift is due to the delayed nucleation

vs. thermal lag of the DSC apparatus. It would be attractive to

consider using Jaentsch-Kreigl’s scheme [8] for correction

of thermal lag effects to see how we could improve the quality of

the data. It should be noted however, that the application of such

a correction will only define the ‘actual’ cooling rate

of the DSC experiment. Since the DSC data are used solely to provide

a representative transition from the melt to the solid state, the

impact of this approximation is diminished. It has no bearing on

solid state PVT data and the final solid state behavioral characteristics

of the injection molded part since these are taken from actual PVT

experiments. This would not be the case if a crystallization kinetics

model was used to calculate the solid state PVT data where a precise

characterization of the model would be vital. Further, the present

uncertainty about the universal acceptability of such models [9]

would make such a kinetics based scheme less robust.

Conclusions

Molding simulation programs have been hampered in their ability

to predict shrinkage of semi-crystalline plastics. The inability

of conventionally generated PVT data to properly

represent the crystallization phenomenon has been a factor. We have

defined an elegant scheme to assemble a representative PVT model

for injection molded parts. This model is created from experimental

data that can be generated with currently available technology.

It does not rely upon crystallization kinetics models which are

as yet, not universally proven. It will permit us to use the PVT

models currently available with the major mold analysis programs

without modification. In future, with advances in the modeling of

crystallization kinetics, it may be possible to better model the

transition from melt to solid based on the original data.

Acknowledgements

We acknowledge the contributions of Craig Montoya who performed

the PVT measurements and Michael Tylenda who performed the DSC measurements.

Thanks also to Dr. Paul Zoller, University of Colorado, Dr. Gibson

Batch of 3M and to Dr. Charles Tucker of the University of Illinois

for their valuable comments.

References

1. V. W. Wang and C. Hieber, ANTEC ’88 Proceedings, 290 (1988)

2. Y. Fakhreddine and P. Zoller, ANTEC ‘91 Proceedings, 1642

(1991)

3) Characterizing Polymers for C-MOLD Simulations, 3rd Ed. AC Technology,

Ithaca NY (1994)

4) Gnomix Inc., 3809 Birchwood Drive, Boulder CO 80304

5) P. Zoller, P. Bolli, V. Pahud, and J. Ackermann, Rev. Sci. Instrum.,

47, 948 (1976)

6) J. He and P. Zoller, ANTEC’92 Proceedings, 1144 (1992)

7) R. M. Shay, Jr., P. H. Foss, and C. C. Mentzer, ANTEC’96

Proceedings, 496 (1996)

8) G. Eder, H. Janeschitz-Kriegl, Proc. IX Annual Meeting of PPS,

452 (1993)

9) T. V. Chan, G. D. Shyu and A. I. Isayev, Polym. Eng. Sci. 35,

733 (1995)

|

|

Figure 1. DSC measurements at different cooling rates

Table 1. Peak Analysis of DSC data at different cooling rates

Figure 2. Solid state PVT of the injection molded part with a heating

transition

Figure 3. Isobaric cooling experiments

Figure 4. Isothermal cooling experiments

Table 2. Conversion, predicted and actual specific volume vs Temperature

at +3 °C/min

Figure 5. Comparison of experimental and calculated PVT data; DSC

cooling experiment is superimposed

|